|

BMW N54 Oil Catch Cans & PCV System

We've seen a lot of descriptions for the crankcase vent system (PCV) on the N54 engine but "hot garbage" may be the most common. Here we're going to look at the N54 PCV system and give some recommendations and advice on how to resolve its multiple issues.

Background

With any engine as you increase your throttle you are creating a vacuum within the engine. This will draw in outside air through your intake but is also designed to pull vapor and gases from within the engine crankcase. Managing the vacuum and the vapor is called Positive Crankcase Ventilation (PCV) or Crankcase Ventilation (CCV). A crucial piece of the system is separating the internal vapor into liquid and gas. In most modern BMWs that involves a "cyclonic separator" which swirls the vapor around - heavier liquid droplets are separated from the gaseous vapor. Liquid is drained downward to the oil pan and the lighter vapor is pulled via vacuum into the intake and then burned up during combustion. Ignition and fuel mapping are designed to function with some oil vapor entering the engine. In recent years the challenge has been to keep this entire process internal to the engine to minimize carbon emissions, i.e. the leakage of oil vapor into the atmosphere.

The N54 PCV is actually two separate systems with unique faults and deficiencies. There is a low-pressure system, aka low side, that works under vacuum or low pressure conditions (idling, light acceleration, off the throttle, etc). And there is a high-pressure system, aka high side, that works when under boost or load. They have separate ports on the top of the valve cover.

Most of our driving is low throttle and not creating much boost so the low side PCV is the most relevant. After going through the cyclonic separators, oil vapor is routed through the bottom edge of the valve cover and through tiny ports in the cylinder head and into the intact tract for each cylinder. The vapor is supposed to enter the combustion chamber from here and get burned up during combustion. A check valve is installed to regulate when this low side path is open or closed. The check valve often fails, especially with higher boost, and too much liquid oil is allowed through the low side circuit. This causes the dreaded carbon build-up on intake valves. Too much oil in the air/fuel mixture will also lower the fuel octane causing loss of power. Replacing the check valve with a stronger one will help eliminate most of this issue. Unlike previous BMW PCV systems, this one is notably simple but fails in execution.

By adding turbocharging to the design the engine becomes highly pressurized. Under boost there needs to be a more direct, faster, and more efficient evacuation of oil and vapor. This happens in the high-side PCV on the N54 engine. When boost reaches a pre-determined level a 1-way valve will open in the valve cover and bypass the low-side circuit. Liquid oil and vapor are sent via a plastic hose from the valve cover directly into the intake air duct for the bank 2 turbo, located at the back of the engine. The liquid oil can drain using the turbo's existing drain line and the vapor will either be burned up by the turbo heat or continue on through the intake system and burned up under combustion. Here again the system is thankfully simple - a flapper valve is the only moving part. If the flapper fails simply replace the plastic hose with a stock part and it should be fine for tens of thousands of miles.

The entire N54 PCV system is internal to the valve cover, with the exception of that high side hose. This internalizes the ventilation to minimize carbon emissions. There is next to zero maintenance required. However, simple does not always mean reliable. The small ports within the PCV can become blocked, the low side check valve can fail, and the high side flapper valve can fail. The valve cover itself may crack or warp, requiring a full replacement. BMW made some great advancements in simple PCV design but as owners have found out, it's far from perfect. There are a number of reasons why the valve cover may need replacement anyway so it seems BMW has planned PCV maintenance to coincide with other work.

N54 Oil Leaks

Problems with the N54 PCV will reveal themselves in different ways, depending on which system is breaking down (or both). You have to do a little investigating on where liquid oil is accumulating. Here are some common N54 oil symptoms and their likely causes:

Oil in the Front Intercooler Piping. Three possible causes: internal turbo oil leak(s), failed flapper valve in valve cover, or blocked oil drain on turbo(s). Start with those in order. You will need to remove additional hoses in the intercooler piping to trace the oil residue back to one turbo in particular. If the rear (bank 2) turbo is showing more oil residue consider that the high-side flapper valve in the valve cover has failed. Check the high-side hose and the turbo inlet air duct at the back of the engine for oil residue. If you find oil from the front turbo you can be sure the internal seals are damaged and leaking and replacement of both turbos is required. Oil drains are done via gravity back to the block so there's very little that can fail, except for a blockage.

Oil & Carbon on Intake Valves. The low-side PCV system has failed. There is a check valve in the low-side port on the valve cover that does a poor job of sealing, even when brand-new. Stronger replacement check valves are available but this is only part of the problem. Past the check valve is an internal passageway that is supposed to distribute oil vapor directly into the cylinder head before the valves, to be burned up in the engine. But with too much liquid oil in the vapor - you guessed it - the intake valves get coated in a light film of oil that builds over time. Low engine temps, from short trips around town, never get the oil hot and thin enough to move freely around the engine and burn off moisture.

Oil in the Spark Plug Holes. Cracked valve cover or leaking valve cover gasket. Not that this could also cause smoke from the tailpipe as oil gets in past the spark plug and into the combustion chamber.

Oil around the Oil Cap or Unexpected Areas. First replace your oil cap as a potential cheap fix. But oil residue in unexpected areas could be a sign of an over-pressurized crankcase. The inlets to the PCV in the valve cover may be blocked and not allowing any oil vapor into the cyclonic separators. Since the vapor will exit through the next weakest point it may likely be the cap (which is baffled to function as a vent). To check for a blockage though requires removing the valve cover so you might as well replace it since the gasket is not available separately. You could use a vented oil cap but this does not fix the root issue.

Smoke from Tailpipe. Oil seals in the turbo(s) failing. See Oil in the Intercooler Piping above (same causes). Oil blow-by past the piston rings. Valve stem seals in cylinder head have failed, allowing oil past the valve stem and into the combustion chamber. Failed valve cover gasket allowing oil into the spark plug hole (see above).

Oil in the Intake Manifold or Throttle Body. Oil seals in the turbo(s) failing. See Oil in the Intercooler Piping above (same causes).

Oil on the Front of the Engine. Leaking valve cover gasket or oil filter housing gasket, nothing to do with the valve cover or PCV.

Vargas competition dual oil catch cans.

Will An Oil Catch Can Help?

If either PCV system worked as intended there would be no benefit to an oil catch can. But the widespread reporting of oil issues, and our own experience, indicate that the factory system is just not up to the task of functioning as designed for very long. The reality for many N54 owners is that oil venting can either be a reoccurring headache or be resolved completely. What we would advise is to first accurately diagnose and understand the oil issues. If either of the check valves is not up to the task then explore the OCC solutions. The beauty of this system is that you can replace them both or replace one and leave the other intact. Personally, we would convert the low side to a OCC to avoid carbon build-up on valves and then replace the high side only if we see evidence of oil getting into the rear turbo.

Some advice on buying an oil catch can: Do not seek inexpensive products that are not as well engineered or do not have the same quality control as the premium solutions - "Buy once. Cry once." The last thing you want to see is an oil leak from your freshly installed OCC kit and have to start all over again. And avoid anything that is "Vent-to-Atmosphere" (VTA). These are small filters on the hose or the catch can that vent oil vapor into the engine bay instead of recirculating it back to the engine. Recirculating PCV is better overall - no oil fumes, no oil residue, and better for the environment.

Is it CARB or EPA legal?

It is not CARB or EPA legal to tamper or modify a part of the emissions system. Is it better to have a malfunctioning factory system than a operational aftermarket solution? No, but that is how BMW legalized the N54 for the US market and that is the only view that CARB and the EPA will accept. The car was tested and certified with the original design and that is the only one that authorities can (rightly) accept. They don't deal in "In theory this is better." It is possible to get a waiver and approval for the OCC alternative but most companies will not bother with the hassle and expense.

What Else Can I Do?

Get out and drive! Avoid short trips where oil never reaches optimum temp and moisture doesn't burn off. Once up to temp, open the throttle and give your engine the opportunity to recirculate oil. Change your driving habits to get the engine and oil to an optimum temp (over 212°F). Getting the oil hot will thin the viscosity and allow it to flow better. It also burns off moisture that will turn the oil into sludge or freeze and block critical passageways. Low RPM and constant minimum throttle will also fail to pull enough vacuum for the crankcase vent to work properly. We encourage regular runs up to high RPM and varying your throttle (an "Italian tune-up"). But for the safety of yourself and others, please drive responsibly.

Use Premium gasoline and engine oil. Premium octane fuel is measured by an anti-knock index rating (AKI). The higher the octane rating the better it resists knocking. Use the best you can so the engine does not reduce power output. Get the most available power and heat to burn off the moisture, carbon, and other contaminants. The same goes for engine oil. Cheap oil will break down more easily, especially at the temps you need. This leads to increased carbon and less protection for your engine internals (increasing wear). Have regular oil changes done to avoid oil contamination. With oil and gasoline you get what you pay for and spending a little more will get you a better product.

Stay on top of preventative maintenance items like your cooling system, MAF/MAP sensors, and oxygen sensors. All of these things feed data back to the engine computer, which then makes decisions on how the engine should perform. The computer will compensate for a poorly-running engine by reducing power output and other strategies to keep the engine running, often without you even aware of the reduction. The goal is to have it operating at its peak output and efficiency so staying on top of maintenance is smart and important.

What's the Plan?

If you want a plan or roadmap for tackling your PCV system here is what we recommend.

Stage 1: Stock Valve Cover & OEM+ Parts.

Consider replacing the valve cover completely for a fresh oil separator and ensure no leaks from a cracked or warped old cover. Replace the low side check valve on a new or used valve cover with a stronger aluminum piece (click here for link). Replace the high side vent hose with an OEM piece (BMW part #11157553949).

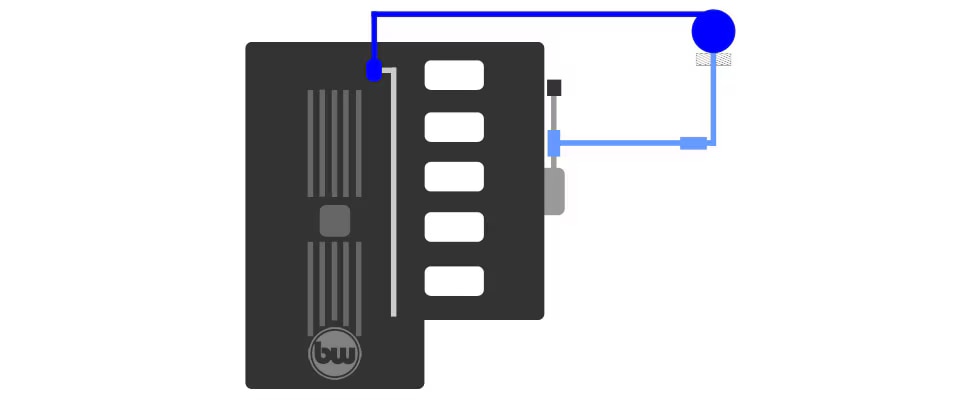

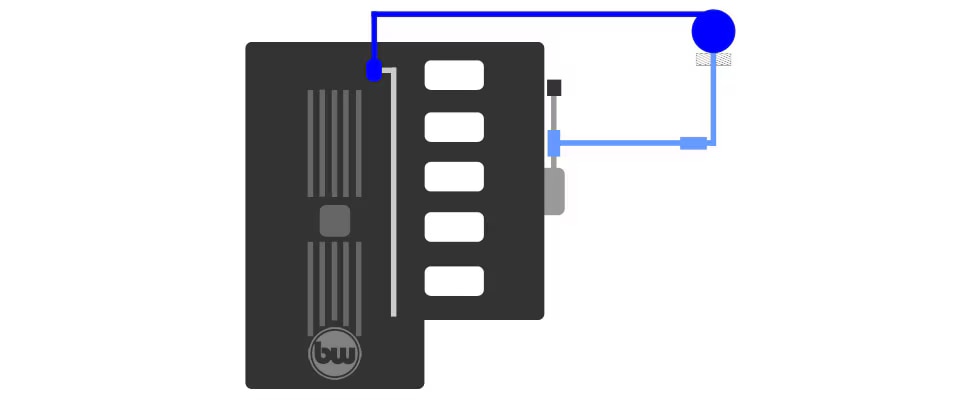

Stage 2a: Low Side Oil Catch Can.

Since most of our driving is in the low-pressure/vacuum environment it may be more important to replace this low side PCV with an oil catch can. This is not a difficult change and involves no major or permanent modifications to the engine (it's reversible). This converts the low side from an internal PCV to an external using the catch can. You can vent the vapor into the engine bay (VTA) but we prefer to recirculate it back into the intake. Vargas has a slick system that includes a check valve and t-fitting for a seamless install on the factory fuel evap valve (cutting and splicing hoses is required). Note that installing an oil catch can interferes with the factory plastic cowl cover and microfilters and they have to be replaced with filters from BMS.

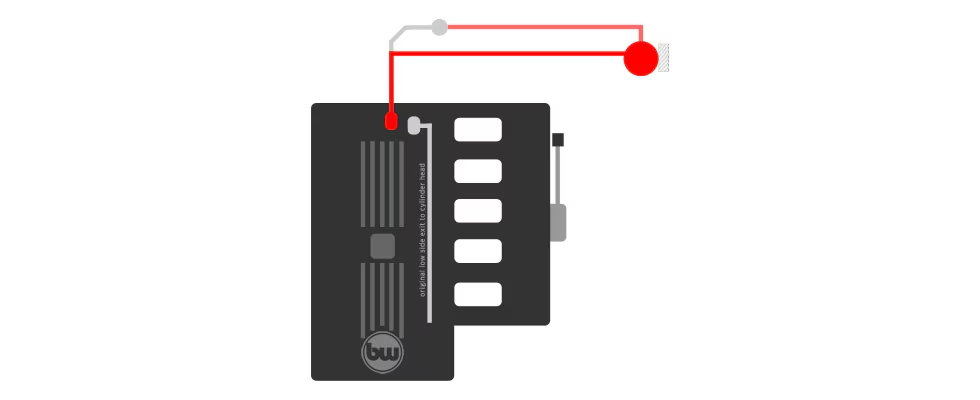

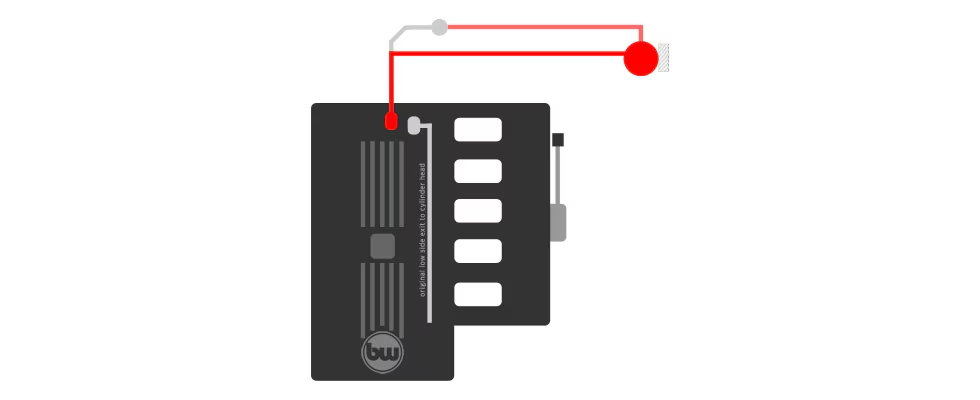

Stage 2b: High Side Oil Catch Can.

There's not a lot to go wrong in the high side system but it is made from fragile plastic. The high side oil catch will use aluminum and premium fittings for a solid venting system. Without the stock high side flapper valve more liquid oil will end up in the catch can instead of your intake and rear turbo. You probably don't need a high side oil catch can with stock turbos and mild boost unless you want a more bulletproof system. For track and race use where you're at full throttle most of the time you will definitely be interested in the high side solution. You can vent vapor to the engine bay and seal off the turbo inlet for a stronger system. But for street use it's better to recirculate the vapor into that turbo inlet at the back of the engine. Note that installing an oil catch can interferes with the factory plastic cowl cover and microfilters and they have to be replaced with filters from BMS.

Stage 3: Vargas Modular Valve Cover & Catch Cans

A more expensive but no-nonsense solution to the entire valve cover and PCV system. This is an aluminum version of the original plastic cover but is simplified down to the bare minimum. The cover does not include any internal oil separators so it requires one or two oil catch cans. It's also easy to add other ports such as vacuum/boost fittings and other crankcase breathers. The modular cover is available as billet or cast aluminum but should only be used for racing or track use.

And Then?

Can the N54 oil circulation system be trouble-free and reliable? Yes it can - with enough understanding and quality engineered solutions. Like the rest of the 335i N54 platform the oil system letdowns can be overcome. Don't give up on the N54 just yet. As the engine and related systems get pushed beyond their original design limits the failures will be identified and addressed. The N54 can be all that it was hyped to be and more!

135i/335i N54 Oil Vent / Circulation Parts:

Background

With any engine as you increase your throttle you are creating a vacuum within the engine. This will draw in outside air through your intake but is also designed to pull vapor and gases from within the engine crankcase. Managing the vacuum and the vapor is called Positive Crankcase Ventilation (PCV) or Crankcase Ventilation (CCV). A crucial piece of the system is separating the internal vapor into liquid and gas. In most modern BMWs that involves a "cyclonic separator" which swirls the vapor around - heavier liquid droplets are separated from the gaseous vapor. Liquid is drained downward to the oil pan and the lighter vapor is pulled via vacuum into the intake and then burned up during combustion. Ignition and fuel mapping are designed to function with some oil vapor entering the engine. In recent years the challenge has been to keep this entire process internal to the engine to minimize carbon emissions, i.e. the leakage of oil vapor into the atmosphere.

The N54 PCV is actually two separate systems with unique faults and deficiencies. There is a low-pressure system, aka low side, that works under vacuum or low pressure conditions (idling, light acceleration, off the throttle, etc). And there is a high-pressure system, aka high side, that works when under boost or load. They have separate ports on the top of the valve cover.

Most of our driving is low throttle and not creating much boost so the low side PCV is the most relevant. After going through the cyclonic separators, oil vapor is routed through the bottom edge of the valve cover and through tiny ports in the cylinder head and into the intact tract for each cylinder. The vapor is supposed to enter the combustion chamber from here and get burned up during combustion. A check valve is installed to regulate when this low side path is open or closed. The check valve often fails, especially with higher boost, and too much liquid oil is allowed through the low side circuit. This causes the dreaded carbon build-up on intake valves. Too much oil in the air/fuel mixture will also lower the fuel octane causing loss of power. Replacing the check valve with a stronger one will help eliminate most of this issue. Unlike previous BMW PCV systems, this one is notably simple but fails in execution.

By adding turbocharging to the design the engine becomes highly pressurized. Under boost there needs to be a more direct, faster, and more efficient evacuation of oil and vapor. This happens in the high-side PCV on the N54 engine. When boost reaches a pre-determined level a 1-way valve will open in the valve cover and bypass the low-side circuit. Liquid oil and vapor are sent via a plastic hose from the valve cover directly into the intake air duct for the bank 2 turbo, located at the back of the engine. The liquid oil can drain using the turbo's existing drain line and the vapor will either be burned up by the turbo heat or continue on through the intake system and burned up under combustion. Here again the system is thankfully simple - a flapper valve is the only moving part. If the flapper fails simply replace the plastic hose with a stock part and it should be fine for tens of thousands of miles.

The entire N54 PCV system is internal to the valve cover, with the exception of that high side hose. This internalizes the ventilation to minimize carbon emissions. There is next to zero maintenance required. However, simple does not always mean reliable. The small ports within the PCV can become blocked, the low side check valve can fail, and the high side flapper valve can fail. The valve cover itself may crack or warp, requiring a full replacement. BMW made some great advancements in simple PCV design but as owners have found out, it's far from perfect. There are a number of reasons why the valve cover may need replacement anyway so it seems BMW has planned PCV maintenance to coincide with other work.

N54 Oil Leaks

Problems with the N54 PCV will reveal themselves in different ways, depending on which system is breaking down (or both). You have to do a little investigating on where liquid oil is accumulating. Here are some common N54 oil symptoms and their likely causes:

Oil in the Front Intercooler Piping. Three possible causes: internal turbo oil leak(s), failed flapper valve in valve cover, or blocked oil drain on turbo(s). Start with those in order. You will need to remove additional hoses in the intercooler piping to trace the oil residue back to one turbo in particular. If the rear (bank 2) turbo is showing more oil residue consider that the high-side flapper valve in the valve cover has failed. Check the high-side hose and the turbo inlet air duct at the back of the engine for oil residue. If you find oil from the front turbo you can be sure the internal seals are damaged and leaking and replacement of both turbos is required. Oil drains are done via gravity back to the block so there's very little that can fail, except for a blockage.

Oil & Carbon on Intake Valves. The low-side PCV system has failed. There is a check valve in the low-side port on the valve cover that does a poor job of sealing, even when brand-new. Stronger replacement check valves are available but this is only part of the problem. Past the check valve is an internal passageway that is supposed to distribute oil vapor directly into the cylinder head before the valves, to be burned up in the engine. But with too much liquid oil in the vapor - you guessed it - the intake valves get coated in a light film of oil that builds over time. Low engine temps, from short trips around town, never get the oil hot and thin enough to move freely around the engine and burn off moisture.

Oil in the Spark Plug Holes. Cracked valve cover or leaking valve cover gasket. Not that this could also cause smoke from the tailpipe as oil gets in past the spark plug and into the combustion chamber.

Oil around the Oil Cap or Unexpected Areas. First replace your oil cap as a potential cheap fix. But oil residue in unexpected areas could be a sign of an over-pressurized crankcase. The inlets to the PCV in the valve cover may be blocked and not allowing any oil vapor into the cyclonic separators. Since the vapor will exit through the next weakest point it may likely be the cap (which is baffled to function as a vent). To check for a blockage though requires removing the valve cover so you might as well replace it since the gasket is not available separately. You could use a vented oil cap but this does not fix the root issue.

Smoke from Tailpipe. Oil seals in the turbo(s) failing. See Oil in the Intercooler Piping above (same causes). Oil blow-by past the piston rings. Valve stem seals in cylinder head have failed, allowing oil past the valve stem and into the combustion chamber. Failed valve cover gasket allowing oil into the spark plug hole (see above).

Oil in the Intake Manifold or Throttle Body. Oil seals in the turbo(s) failing. See Oil in the Intercooler Piping above (same causes).

Oil on the Front of the Engine. Leaking valve cover gasket or oil filter housing gasket, nothing to do with the valve cover or PCV.

Vargas competition dual oil catch cans.

Will An Oil Catch Can Help?

If either PCV system worked as intended there would be no benefit to an oil catch can. But the widespread reporting of oil issues, and our own experience, indicate that the factory system is just not up to the task of functioning as designed for very long. The reality for many N54 owners is that oil venting can either be a reoccurring headache or be resolved completely. What we would advise is to first accurately diagnose and understand the oil issues. If either of the check valves is not up to the task then explore the OCC solutions. The beauty of this system is that you can replace them both or replace one and leave the other intact. Personally, we would convert the low side to a OCC to avoid carbon build-up on valves and then replace the high side only if we see evidence of oil getting into the rear turbo.

Some advice on buying an oil catch can: Do not seek inexpensive products that are not as well engineered or do not have the same quality control as the premium solutions - "Buy once. Cry once." The last thing you want to see is an oil leak from your freshly installed OCC kit and have to start all over again. And avoid anything that is "Vent-to-Atmosphere" (VTA). These are small filters on the hose or the catch can that vent oil vapor into the engine bay instead of recirculating it back to the engine. Recirculating PCV is better overall - no oil fumes, no oil residue, and better for the environment.

Is it CARB or EPA legal?

It is not CARB or EPA legal to tamper or modify a part of the emissions system. Is it better to have a malfunctioning factory system than a operational aftermarket solution? No, but that is how BMW legalized the N54 for the US market and that is the only view that CARB and the EPA will accept. The car was tested and certified with the original design and that is the only one that authorities can (rightly) accept. They don't deal in "In theory this is better." It is possible to get a waiver and approval for the OCC alternative but most companies will not bother with the hassle and expense.

What Else Can I Do?

Get out and drive! Avoid short trips where oil never reaches optimum temp and moisture doesn't burn off. Once up to temp, open the throttle and give your engine the opportunity to recirculate oil. Change your driving habits to get the engine and oil to an optimum temp (over 212°F). Getting the oil hot will thin the viscosity and allow it to flow better. It also burns off moisture that will turn the oil into sludge or freeze and block critical passageways. Low RPM and constant minimum throttle will also fail to pull enough vacuum for the crankcase vent to work properly. We encourage regular runs up to high RPM and varying your throttle (an "Italian tune-up"). But for the safety of yourself and others, please drive responsibly.

Use Premium gasoline and engine oil. Premium octane fuel is measured by an anti-knock index rating (AKI). The higher the octane rating the better it resists knocking. Use the best you can so the engine does not reduce power output. Get the most available power and heat to burn off the moisture, carbon, and other contaminants. The same goes for engine oil. Cheap oil will break down more easily, especially at the temps you need. This leads to increased carbon and less protection for your engine internals (increasing wear). Have regular oil changes done to avoid oil contamination. With oil and gasoline you get what you pay for and spending a little more will get you a better product.

Stay on top of preventative maintenance items like your cooling system, MAF/MAP sensors, and oxygen sensors. All of these things feed data back to the engine computer, which then makes decisions on how the engine should perform. The computer will compensate for a poorly-running engine by reducing power output and other strategies to keep the engine running, often without you even aware of the reduction. The goal is to have it operating at its peak output and efficiency so staying on top of maintenance is smart and important.

What's the Plan?

If you want a plan or roadmap for tackling your PCV system here is what we recommend.

Stage 1: Stock Valve Cover & OEM+ Parts.

Consider replacing the valve cover completely for a fresh oil separator and ensure no leaks from a cracked or warped old cover. Replace the low side check valve on a new or used valve cover with a stronger aluminum piece (click here for link). Replace the high side vent hose with an OEM piece (BMW part #11157553949).

Stage 2a: Low Side Oil Catch Can.

Since most of our driving is in the low-pressure/vacuum environment it may be more important to replace this low side PCV with an oil catch can. This is not a difficult change and involves no major or permanent modifications to the engine (it's reversible). This converts the low side from an internal PCV to an external using the catch can. You can vent the vapor into the engine bay (VTA) but we prefer to recirculate it back into the intake. Vargas has a slick system that includes a check valve and t-fitting for a seamless install on the factory fuel evap valve (cutting and splicing hoses is required). Note that installing an oil catch can interferes with the factory plastic cowl cover and microfilters and they have to be replaced with filters from BMS.

Stage 2b: High Side Oil Catch Can.

There's not a lot to go wrong in the high side system but it is made from fragile plastic. The high side oil catch will use aluminum and premium fittings for a solid venting system. Without the stock high side flapper valve more liquid oil will end up in the catch can instead of your intake and rear turbo. You probably don't need a high side oil catch can with stock turbos and mild boost unless you want a more bulletproof system. For track and race use where you're at full throttle most of the time you will definitely be interested in the high side solution. You can vent vapor to the engine bay and seal off the turbo inlet for a stronger system. But for street use it's better to recirculate the vapor into that turbo inlet at the back of the engine. Note that installing an oil catch can interferes with the factory plastic cowl cover and microfilters and they have to be replaced with filters from BMS.

Stage 3: Vargas Modular Valve Cover & Catch Cans

A more expensive but no-nonsense solution to the entire valve cover and PCV system. This is an aluminum version of the original plastic cover but is simplified down to the bare minimum. The cover does not include any internal oil separators so it requires one or two oil catch cans. It's also easy to add other ports such as vacuum/boost fittings and other crankcase breathers. The modular cover is available as billet or cast aluminum but should only be used for racing or track use.

And Then?

Can the N54 oil circulation system be trouble-free and reliable? Yes it can - with enough understanding and quality engineered solutions. Like the rest of the 335i N54 platform the oil system letdowns can be overcome. Don't give up on the N54 just yet. As the engine and related systems get pushed beyond their original design limits the failures will be identified and addressed. The N54 can be all that it was hyped to be and more!

135i/335i N54 Oil Vent / Circulation Parts:

| Sort by Name | Sort by Price |